Introduction: What Lies Beneath the Surface?

When you think about offshore oil platforms, underwater pipelines, or subsea cables, it’s easy to picture only what’s above the surface — the rigs, the equipment, and the ships. But what about the massive network of structures hidden beneath the ocean floor that make these systems possible?

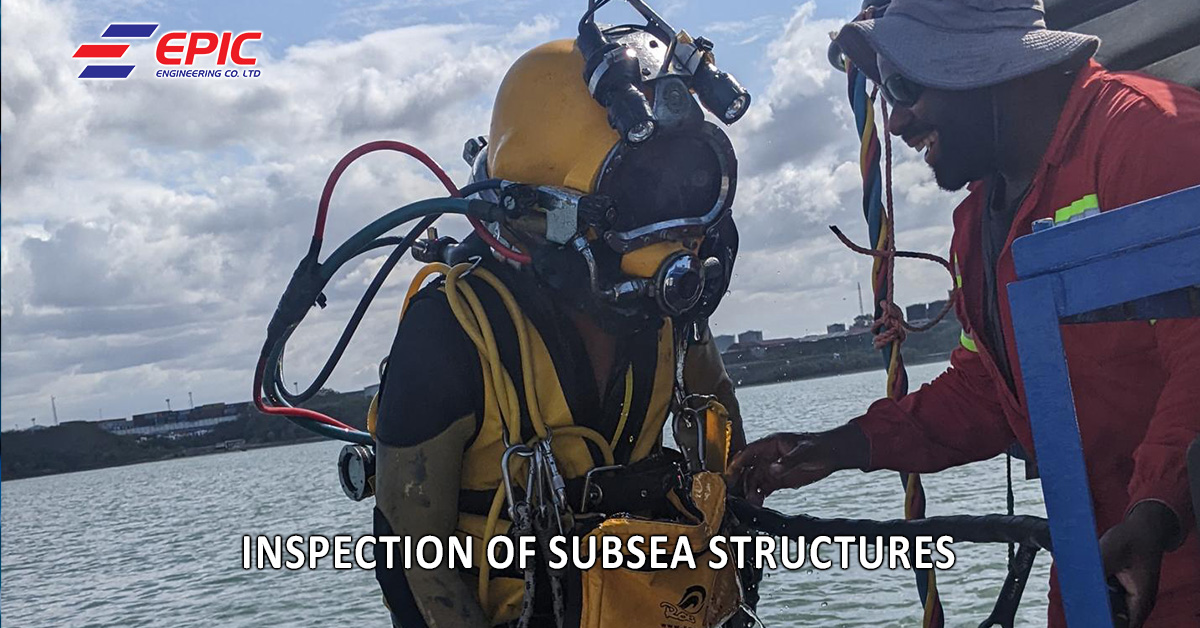

The real backbone of offshore operations lies underwater. These subsea structures—from pipelines and risers to manifolds and wellheads—face extreme conditions such as high pressure, corrosion, marine growth, and constant mechanical stress. That’s why inspection of subsea structures is not just a routine task; it’s a critical safety and reliability measure.

At Epic Engineering Company Limited, we understand the complexities of underwater infrastructure. Our inspection solutions ensure that subsea assets remain structurally sound, environmentally compliant, and operationally efficient throughout their service life.

In this article, we’ll explore what subsea inspections are, why they matter, the methods used, and how Epic Engineering helps industries across East Africa maintain offshore integrity and safety.

What Are Subsea Structures?

Subsea structures are components of underwater infrastructure that support exploration, production, and transportation of resources such as oil, gas, and renewable energy. These systems include:

-

Subsea pipelines and flowlines

-

Manifolds and templates

-

Risers and umbilicals

-

Wellheads and X-mas trees

-

Subsea control systems and anchors

Each structure plays a vital role in connecting offshore production facilities to onshore processing plants.

Over time, however, exposure to saltwater corrosion, sediment movement, and marine organisms can compromise their integrity. This is where regular inspection becomes essential.

Why Subsea Inspection Is Crucial

Imagine an underwater pipeline transporting thousands of barrels of crude oil daily. A small, undetected crack could lead to environmental pollution, costly downtime, or catastrophic failure. Subsea inspection prevents that by identifying issues early and guiding corrective actions before they escalate.

Here’s why subsea structure inspection is indispensable:

1. Ensures Structural Integrity

Inspections help detect cracks, weld failures, or corrosion that could weaken subsea structures, ensuring they remain fit for service.

2. Enhances Safety

Preventing leaks, collapses, or equipment failures safeguards personnel, assets, and the environment.

3. Reduces Downtime

Early detection allows timely maintenance, avoiding costly unscheduled shutdowns.

4. Extends Asset Lifespan

Proper monitoring and preventive maintenance prolong the operational life of subsea systems.

5. Regulatory Compliance

Many industries must meet strict safety and environmental regulations. Regular inspections help ensure compliance with ISO standards and offshore safety frameworks.

Types of Subsea Inspections

Subsea inspection activities can be broadly classified into three categories, depending on timing and purpose.

1. Baseline Inspection

Conducted after installation, this inspection documents the initial condition of the structure. It serves as a reference point for future inspections.

2. Periodic Inspection

Scheduled at regular intervals, it identifies progressive deterioration like corrosion, coating damage, or marine growth.

3. Special Inspection

Triggered by specific events such as storms, equipment impact, or operational anomalies.

Each of these inspection types contributes to a comprehensive asset integrity management plan.

Inspection Techniques for Subsea Structures

Underwater inspection isn’t a one-size-fits-all approach. Depending on depth, visibility, and type of structure, engineers use a combination of visual, acoustic, and non-destructive testing (NDT) methods.

Let’s look at the most common techniques.

1. Visual Inspection

This is the most straightforward method, involving divers or Remotely Operated Vehicles (ROVs) equipped with HD cameras and lighting to visually assess structures.

It helps detect:

-

Corrosion and coating failure

-

Marine growth

-

Weld cracks

-

Structural deformation

Visual inspections provide an overall picture of asset health and guide where deeper analysis is needed.

2. Ultrasonic Testing (UT)

Ultrasonic waves are used to detect internal flaws or measure wall thickness in metallic components.

UT is particularly useful for:

-

Identifying corrosion under insulation

-

Measuring metal loss

-

Detecting subsurface cracks

Advanced systems now use ROV-mounted ultrasonic sensors, allowing inspections at great depths without diver intervention.

3. Magnetic Particle and Eddy Current Testing

These methods help locate surface and near-surface defects in ferromagnetic materials. Eddy current testing is ideal for detecting corrosion in non-ferrous materials and can even be performed through coatings.

4. Cathodic Protection (CP) Surveys

Subsea structures often use Cathodic Protection systems to prevent corrosion. CP surveys measure electrical potentials across the structure to verify that the system is functioning correctly.

Epic Engineering provides CP monitoring and maintenance as part of its corrosion management services, ensuring long-term protection for offshore assets.

5. Acoustic and Sonar Imaging

For areas with poor visibility, acoustic tools such as multibeam sonar and side-scan sonar create high-resolution images of subsea assets.

These methods are invaluable for mapping seabed conditions, identifying debris, or locating buried pipelines.

6. Laser Scanning and Photogrammetry

Modern inspections employ laser scanning and 3D photogrammetry to generate detailed digital models of subsea structures.

These models enable engineers to track deformation, corrosion growth, and alignment issues over time with extreme precision.

7. Autonomous Underwater Vehicles (AUVs)

For deep-sea inspections, AUVs are deployed to gather data autonomously. They cover large areas efficiently, capturing detailed sonar and photographic information without requiring surface control.

Challenges in Subsea Inspection

Operating beneath the ocean surface is no easy task. Engineers face numerous challenges, such as:

-

Limited visibility due to turbidity or marine growth

-

High pressure and low temperatures at depth

-

Strong currents that affect ROV and diver stability

-

Accessibility issues for buried or complex structures

-

Data interpretation difficulties from noisy or incomplete signals

Overcoming these obstacles requires advanced technology, specialized expertise, and strict safety standards — all of which Epic Engineering delivers with precision.

Epic Engineering’s Approach to Subsea Inspections

At Epic Engineering Company Limited, we don’t just perform inspections — we provide end-to-end integrity management solutions tailored to our clients’ needs.

Our Inspection Capabilities Include:

-

ROV-based visual and ultrasonic inspections

-

Diver-assisted NDT and corrosion mapping

-

Cathodic protection and potential surveys

-

3D laser scanning and photogrammetry

-

Structural assessment and reporting

-

Post-inspection maintenance and repairs

Our Core Strengths

-

Certified under ISO 9001, ISO 14001, and ISO 45001

-

Multidisciplinary expertise across mechanical, electrical, and marine engineering

-

Compliance with international offshore standards

-

Local experience in East African marine and industrial environments

We understand the unique challenges of subsea engineering in the Tanzanian region — from offshore energy platforms to undersea pipelines — and provide inspection solutions designed for accuracy, safety, and efficiency.

Integrating Technology and Experience

What sets Epic Engineering apart is our combination of skilled personnel and cutting-edge technology.

Our teams utilize ROVs, AUVs, ultrasonic probes, and 3D scanners to capture data even in the most challenging subsea conditions. The data is then processed using advanced software analytics, transforming raw visuals into actionable insights.

This digital transformation enables predictive maintenance — helping clients plan interventions before failures occur, saving both time and money.

Environmental and Safety Considerations

Subsea inspections don’t just protect infrastructure; they also protect the marine environment.

Epic Engineering adheres to ISO 14001 environmental standards, ensuring all inspection operations minimize ecological disturbance. We use low-impact inspection methods, reduce vessel emissions, and follow strict protocols to prevent marine contamination.

Moreover, our commitment to ISO 45001 occupational safety guarantees that every project prioritizes the well-being of divers, engineers, and support personnel.

Applications Across Industries

Subsea inspection isn’t limited to offshore oil and gas. Epic Engineering provides solutions for a wide range of industries, including:

-

Oil & Gas – Pipeline, riser, and wellhead integrity

-

Marine Infrastructure – Piers, jetties, and underwater foundations

-

Renewable Energy – Offshore wind and tidal systems

-

Telecommunication – Submarine cable inspections

-

Water Utilities – Intake tunnels and submerged pipelines

Our multidisciplinary background allows us to customize inspection programs to each sector’s unique operational demands.

The Future of Subsea Inspection

Technology continues to reshape underwater inspection. Emerging trends include:

-

AI-powered defect detection for faster data analysis

-

Digital twins that replicate real-time subsea asset conditions

-

Augmented reality (AR) for remote collaboration

-

Machine learning for predictive maintenance models

Epic Engineering stays ahead of the curve by adopting these next-generation technologies to deliver smarter, safer, and more sustainable subsea solutions.

Conclusion: Protecting the Hidden Foundations of Industry

Subsea structures may be out of sight, but they should never be out of mind.

Regular inspection is essential to ensure the safety, reliability, and performance of underwater assets that power industries and economies.

At Epic Engineering Company Limited, we combine technical expertise, modern tools, and global best practices to help clients safeguard their subsea investments — ensuring long-term efficiency, compliance, and peace of mind.

So, whether you operate an offshore platform, marine terminal, or underwater pipeline, you can trust Epic Engineering to deliver inspection excellence beneath the surface.

Frequently Asked Questions (FAQs)

1. What is the main purpose of subsea structure inspection?

To assess the condition and integrity of underwater assets, identify damage or corrosion, and ensure continued safe operation.

2. How often should subsea structures be inspected?

Typically every 1–3 years, depending on environmental conditions, asset type, and regulatory requirements.

3. What tools are used for subsea inspections?

Common tools include ROVs, ultrasonic probes, sonar systems, laser scanners, and cameras.

4. Can inspections be done without divers?

Yes, most modern inspections use ROVs or AUVs for deepwater and high-risk environments, reducing the need for divers.

5. Why choose Epic Engineering for subsea inspection services?

Because Epic Engineering combines ISO-certified quality, advanced technology, and local expertise, ensuring accurate, efficient, and safe inspection of all underwater assets.